# Geotextiles Manufacturing Plant: Production and Quality Control

## Introduction to Geotextiles Manufacturing

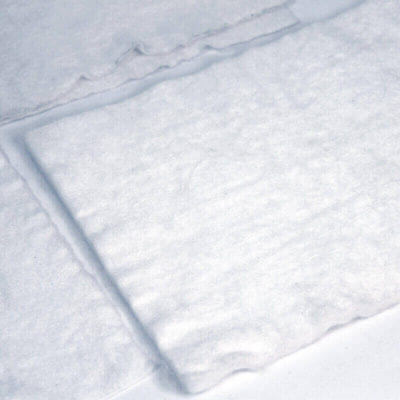

Geotextiles are permeable fabrics used in association with soil, having the ability to separate, filter, reinforce, protect, or drain. The production of geotextiles involves a series of complex processes that ensure the final product meets the required standards for various applications. A geotextiles factory is equipped with advanced machinery and technology to produce high-quality geotextiles efficiently.

## Production Process in a Geotextiles Factory

The production process in a geotextiles factory typically involves several key stages:

### 1. Raw Material Selection

The first step in geotextile manufacturing is the selection of raw materials. Common materials include polypropylene, polyester, and polyethylene. These materials are chosen based on their strength, durability, and resistance to environmental factors.

### 2. Fiber Extrusion

Once the raw materials are selected, they undergo extrusion to form fibers. This process involves melting the polymer and forcing it through spinnerets to create continuous filaments. These filaments are then cooled and solidified.

### 3. Web Formation

The extruded fibers are laid down to form a web. This can be done through various methods such as carding, air-laying, or spunbonding. The web formation process determines the initial structure and properties of the geotextile.

### 4. Bonding

After web formation, the fibers need to be bonded together to create a cohesive fabric. Bonding can be achieved through thermal, chemical, or mechanical means. Thermal bonding is the most common method, where heat is applied to melt the fibers slightly, allowing them to fuse together.

### 5. Finishing

The final step in the production process is finishing. This may involve treatments to enhance the geotextile’s properties, such as adding UV stabilizers, anti-static agents, or flame retardants. The fabric is then rolled and prepared for shipment.

## Quality Control in Geotextiles Manufacturing

Quality control is a critical aspect of geotextile production. A geotextiles factory must adhere to strict quality standards to ensure the final product performs as expected in its intended application. Key quality control measures include:

### 1. Material Testing

Raw materials are tested for their physical and chemical properties before being used in production. This ensures that only high-quality materials are used, which directly impacts the performance of the geotextile.

### 2. In-Process Monitoring

Throughout the production process, various parameters are monitored to ensure consistency and quality. This includes checking the thickness, weight, and tensile strength of the geotextile at different stages.

### 3. Final Product Testing

Before the geotextiles are shipped, they undergo rigorous testing to verify their performance characteristics. Tests may include puncture resistance, tear strength, permeability, and durability under various environmental conditions.

### 4. Certification and Compliance

A reputable geotextiles factory will have certifications from recognized industry bodies. These certifications ensure that the factory adheres to international standards and best practices in geotextile manufacturing.

## Conclusion

The production of geotextiles in a manufacturing plant involves a series of carefully controlled processes to ensure the final product meets the required standards. From raw material selection to final product testing, each step is crucial in delivering high-quality geotextiles that perform effectively in their intended applications. Quality control measures are integral to the manufacturing process, ensuring that the geotextiles produced are reliable, durable, and fit for purpose.

Keyword: Geotextiles factory

Comments are closed